Power and Cruising

We offer all levels of bottom preparation and painting options for power boats and cruising sailboats.

Choose from our preparation options based upon the condition of your bottom paint, and the paint you want from Pettit, Interlux, ZSpar, Blue Water Marine, Woolsey and all industry leading paint brands.

What separates our standard bottom jobs from a lot of other boatyard’s bottom jobs is we sand everyone of the, we don’t just powerwash the boat and then paint. We actually tent the boat off with heavy mil visquene all the away around it, from the hull to the ground. We go inside the tent with full respirator and protective gear on and we sand the bottom of the entire boat before we put the paint on. We also spot-prime if necessary where areas are down to bare gelcoat.

We do a lot of brand new boats and here we use a 6 coat application process. We start with a mold-release remover, we solvent bathe the whole boat, we cut the waterline in, we sand it to 80 grit production spec, we put 3 coats of Interlux InterProtect 2000 Epoxy Primer on and then 3 coats of whatever kind of bottom paint we are using.

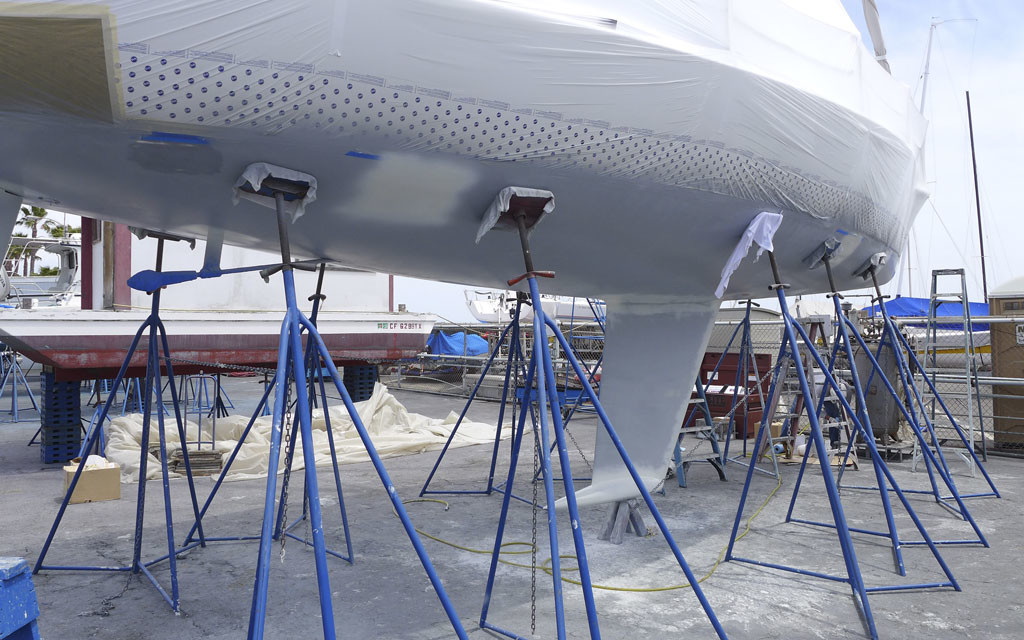

Racing

We offer fairing, foil templating, and all racing finishes from polished epoxy to burnished antifouling. We also install kelp windows, kelp knives and camera systems.

This a Farr 40 that was stripped all the way down to bare gelcoat. We put 3 Epoxy Prime layers of Interprotect 2000 on it and then sprayed it with a white Petit Vivid Bottom which is a Biocide based Racing Paint. We also have the option of putting a Graphite kit in this paint, making it a light grey and a little bit harder.

We spray all of our Racing bottoms with a High Pressure Gun, this allows us to produce a very flat and smooth finish and then we hand burnish the finishes before they go in the water. We can do this with a variety of paints from VC Offshore to Petit Vivid to ECONEA, a metal free anti-fouling agent, as well as Modified Alkaline Epoxy Paints such as Petit Trinidad. We can uses Z Spar Protector for racing finishes or whatever the customer wants.

LP Paint Finishes

Harbor Marineworks is an Awlgrip and Sterling Linear Polyurethane authorized application facility. We provide custom hull and decking jobs, full paint restorations, mast and parts painting, waterline and cove stripes. Our 60’ x 28’ spray tent can comfortably accommodate boats up to 45’, and temporary structures can accommodate larger vessels for atmosphere controlled perfection.

LP Painting is often used a gelcoat restoration method where the gelcoat is dead or damaged from the sun and rather then re-gelcoat the boat, we seal it up with epoxy and put an LP finish on it. The Awlgrip that we use is a true Urethane so it is basically like coating the boat with a flexible liquid plastic. As it catalyzes there’s a clear that comes to the surface and glazes off and that is what gives it a gloss and also provides UV protection for the paint so the sun doesn’t damage it as much.

We like to shoot Awlgrip, we are an Awlgrip Application Facility and we can still shoot the true Awlgrip which other yards in the Los Angeles area can no longer use due to the VOC laws in that area.

We do attract business from the Los Angeles area since we shoot Awlgrip, not Awlgrip2 which is the low solvent VOC.

Custom name Painting

Our on-site artist hand paints custom logos, boat names, hailing ports and pin striping.

We also provide vinyl graphic design and application.